NT5

|

|

|

|

|

|

Objectives:

-

To provide an interesting and rewarding after-hours project to have fun with.

-

To see how much static thrust we can produce with a jet made from a truck turbo-charger.

-

To study the feasibility of building a low cost 75 or 100 kW demand-displacement co-generation facility.

-

To discover and explore other possible uses of a turbo-charger as a jet engine or free-shaft gas turbine.

NT/5 is our most advanced turbocharger turbine to date. With better funding and a lot more experience, we were able to take our experimental turbine project to the next level.

Project Chronology:

November 29I've finally got the new turbo, it has a huge (4" inducer) compressor and looks great. I have also ordered a banner fiber optic sensor that will be used to measure turbine speed.

New T18-"special" turbo(front view)

New T18-"special" turbo (rear view)

T18-"special" cartridge.(note the shape of the compressor wheel, lovely!)

December 05

We bench fired the original NT/4 reverse flow, swirl combustor. We used a gas powered leaf blower to blow air into the air casing and burned propane gas to roughly simulate combustor operation. With no turbine mounted, we can observe the flame directly by looking up the flame tube.

When we connect a second 100lb propane tank and crank it, the combustor roars with the flame extending 12" past the end of the opening! The air blast (observed by standing 12 ft behind the combustor outlet) quadruples over the blast produced by the blower alone with no flame, and it gets real hot too!

Since the combustor pressure during this simulation is only about 15 psia, and normal pressure is up to 30psia, we have concluded that the flame shape and characteristics observed are not likely to be representative of actual operation, therefore we need windows in the air casing to observe the flame during actual turbine operation. We're learning, slowly.

![]()

Flame Tube. With old air casing flange (center.- right) and integral IIM tube (far left).

IIM (Injector/Igniter Module). (previously threaded onto end of flame tube to retain air casing).

December 08

I pressure tested a combustor flame observation window today using double clear glass cutting goggle lenses mounted in a 1 1/2" pipe union. The glass burst at about 100 psi. I will try again with a piece of solid 1/4" glass from the local glass shop.

We have about 3 hours running time on the combustor now and have learned a great deal! I tried varying the amount of combustion air holes around the fuel injector and found that the best looking flame (less holes in the primary zone) lights and looks great, but produces a hot spot on one side of the flame tube. When we add holes, the flame is harder to light, pops into a rose bud shape almost immediately, but does not produce any hot spots. We're not sure how to proceed at this point.

December 10

The 3D solid model of the NT/5 project is going well. The solid model allows us to visualize placement of components and by having a virtual model of the engine, components and test cell (stand), We can work on the layout easily.

December 15

I finally got the Banner fiber optic sensor, hooked it up with a nine volt battery and spun a piece of 1.25" dia. cardboard with four black pie shaped marks on it in a Dremel tool (another one of Springer's ideas). I had to switch to high speed mode (50 microsecond response) and was able to register 1,800 Hz on my Beckman Circuit mate DVM, this works out to 27,000 rpm. The slowest no load speed was 13,350 rpm, the rating on the tool says adjustable from 5,000 - 30,000 rpm. they lie! The Banner D12SP6FPY sensor works great and appears to be the correct choice as far as I am concerned, I spent hours farting around with my own design before I could afford this device.

Fiber Optic Sensor

Fiber Optic Sensor

December 23

Here is a view of the thrust measuring engine mount sub-system. The turbine housing and the combustor will sandwich the red 3/8 thick mounting plate, the entire jet will be hanging off the side of the pivot shaft. Thrust acting through a 6" moment arm (the turbine housing) will produce a torque in the pivot shaft, this torque will act through the long 20" moment arm to produce a force that can be measured by the 50 lb. electronic load cell at the bottom. The entire engine mount sub-system is being made of laser cut type 304 stainless steel. Pivot shaft rotation and jet movement are expected to be imperceptible.

NT/5 engine mount sub-system. (pivot shaft: pink, bearings: blue, turbine exhaust flange & combustor mount: red, load cell: cyan).

NT/5 engine mount sub-system. (pivot shaft: pink, bearings: blue, turbine exhaust flange & combustor mount: red, load cell: cyan).

Load Cell (+/- 50 Lbf capacity).

Load Cell (+/- 50 Lbf capacity).

December 27

I spoke to an engineer at Kendall Lubricants, he says the best oil to use in my jet is Synthetic 5W 30 motor oil. Apparently this oil is relatively thin when cold, (it has a low viscosity index) this will reduce drag and really help at start-up. 5W 30 oil is thinner than the 15W40 Diesel oil I have been using, so I'm hoping it will lower EGT. Synthetic oils are very high quality lubricants that should generally do a better job all around and are a better conductors of heat than regular oils. He also said that ATF and turbine oils are not suitable for automotive turbo chargers for various reasons.

December 28

We have now run about 6 hours of experiments and test burns with the combustor and leaf blower. It seems to work best with all the back wall air holes around the IIM plugged, (with window putty). The flame lights easily, even with the leaf blower at full throttle, the flame rotates nicely in the center of the flame tube and there are no hot spots even with both 100 pounders cranked. I have determined that the air casing to flame tube joint must be re-worked because it leaks like mad due to thermal expansion, this means we will also have to rearrange the IIM (injector/igniter module) mounting.

Combustor Flame (low power).

Combustor Flame (low power).

Combustor Flame (full power).

Combustor Flame (full power).

The results were impressive, at lower air flows and fuel settings, the flame appears as a rotating cigar shaped blue region floating nicely in the center of the flame tube. (see photo below) At full throttle on the leaf blower and with more propane flow, the flame pops into a "rose bud" shape and touches the flame tube walls, although no hot spots appear.

January 04

I have spent several hours re-working the air casing to flame tube joint and the IIM tube. The air casing is now secured with a stainless steel flex-clamp. The air seal is maintained by a 45 degree taper seat machined on both halves of the joint. I made both flanges on a lathe from mechanical tube and heli-arced one onto the air casing and one on top of the old flange on the flame tube. (I had to cut the old flange and about an inch of material off the bottom of the air casing.

Combustor Joint (partly open with clamp removed. air casing on right).

Combustor Joint (partly open with clamp removed. air casing on right).

Since the flame tube expands and contracts so much with heat, I decided to rework the IIM tube so that it floats in the back of the flame tube. The IIM now stays fixed to the air casing, screwed inside the new IIM tube. The IIM tube is just a piece of 1 1/2" pipe with 8 - 11/32 holes drilled radially around it. The holes will allow primary air to swirl down the 1/8" annular gap between the IIM and the IIM tube.

Old Flame Tube Back wall(to be cut off).

Old Flame Tube Back wall(to be cut off).

New Floating IIM Assy. (flame tube - left, IIM tube - ctr., IIM - right).

New Floating IIM Assy. (flame tube - left, IIM tube - ctr., IIM - right).

January 05

I test fired the combustor with the new air casing to flame tube seal and the new IIM tube today. The flame lights easily and forms a tapered corkscrew shape at any blower speed. The flame stays in a corkscrew shape and does not touch the flame tube walls at all! Even with both propane tanks wide open. At first I was happy to see this, but then I realized, because of the lack of jet blast and the nasty odor, that the fuel is not burning completely and the flame is not burning up in the primary zone where it should be. I think more air is needed in the primary zone.

The next step is to make a sight glass so we can see what's happening. Then we need to drill some primary air holes in the back wall around the IIM. We will need to make some kind of adjustable collar to allow us to quickly adjust the area of the air holes during testing.

January 12

Not one but two sight glasses are now installed in the air casing. One looking up towards the turbine, and one looking down towards the fuel injector. I used 1/4" thick boiler sight glasses, these are designed for high temperature and fit on the end of a piece of 1-1/2" pipe with a big union nut. I had to elongate one of the dilution air holes to provide a better view of the flame, so I elongated all four holes around the flame tube at that point so as to keep things symmetrical. I also drilled a pattern of 3/16" and 1/8" holes around the IIM on the back wall of the flame tube, we will continue to use window putty to temporarily block selected holes during combustor testing.

January 14

Today I made a high performance air eductor to replace the leaf blower during combustor testing. This device is basically a 3" dia by 8" long venturi with a 3/8" high pressure nozzle in the center. The nozzle is connected to our main air line in the shop (we have a 50HP compressor) with twin 1/2" air lines and is controlled by a 3/4" ball valve. With the valve full open, tons of air is drawn into the intake producing a gale force wind out the exhaust and a deafening roar. This noisy little thing greatly out performs the 3HP leaf blower, I'm dying to try running the combustor with it.

January 15

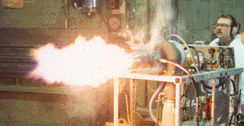

SHOCKWAVE CITY!!! Today I made my first Tiger Stripe Shockwave! We ran the combustor on shop air directly, the eductor did not produce the desired pressure, so we just took the 3/4" air valve and connected it to the combustor air tube. We clamped a piece of 1/2" steel plate with a 3/4" hole punched in it over the exhaust flange to simulate the pressure drop caused by the turbine. With the air on full and no flame, the combustor air pressure was about 8 PSI, with both fuel valves at full blast the pressure jumped to 20 psi and a 18 inch long striped shock wave blasted from the hole. The sound is deafening, my brother counted 8 mach diamonds in the jet exhaust, YES!!!

Combustor Test-Burn(with 3/4" orifice plate).

Combustor Test-Burn(with 3/4" orifice plate).

![]() Shock-Wave (mach diamonds are visible on left).

Shock-Wave (mach diamonds are visible on left).

The sight glasses worked great. (see black lens caps on top of air casing in photo above) We were surprised to see yellow flames inside the combustor when it was working at high pressure with the orifice plate, all the low pressure tests with the leaf blower showed blue flames. We are anxious to get the turbo mounted and running now.

January 24

The 14ga. and 3/16" thick LASER cut stainless pieces for the engine mount subsystem finally arrived today. The parts look great! I hope to TIG weld everything together, at least the main beam for the load cell, tomorrow.

February 06

The engine mount subsystem is finished and the air intake Assy. with start air injector and fiber optic probe is nearly done. I expect to run NT/5 for the first time within the next few days if all goes well. I have started planning the free shaft turbine and speed reducer portion of the project. I sent this document to several gear manufacturers on the web, but no one seems to have much to offer.

February 12

The NT/5 TurboJet ran for the first time today after work. The jet starts easy but much work is needed. I will post more details later.

Clickto hear NT/5 spool-up!

February 14

I ran NT/5 again today after work. The engine mounting sub-system is barely visible in this photo.

NT/5 TurboJet (ready to run for the first time).

February 15

Since starting NT/5 for the first time, we have made several changes. - changed the oil from 15W40 diesel to 5W30 synthetic, this produced an increase in cranking speed from about 100 rpm with cold 15W40 to 6,000 rpm with slightly warm 5W30 at 50 psi. - increased the oil supply line from #4 to #6, getting quite a pressure drop across the hose with the cold 15W40. - re-curved the air impingement nozzle so it points more in the direction of rotation, this made a big improvement in cranking speed. - hooked up the tach sensor to a frequency counter, have to multiply the readings by 60 to get rpm, but otherwise it works great! We are now ready to refine the design by methodically making changes and recording our observations.

February 25

Phil and I were finally able to get NT/5 to rock a little after several hours of experimental work on the primary zone air holes. The compressor is big, possibly too big. We installed a huge 1" ID ball valve in the compressor discharge to act as an air bleed. We can run 15 psi at 41,000 rpm with the air bleed wide open and blasting like crazy. I can't wait to pipe this bypass air into the tail pipe for after burning!

We are having a hard time to get adequate fuel pressure from the propane tanks in the cold weather. I have ordered a K cylinder of hydrogen, we'll see how it works on the weekend.

February 27

Here is a photo of a Caterpillar diesel turbocompounding system I saw in a magazine. The turbo has a separate free shaft power turbine that helps drive the crank through a geared drive shaft. This type of free shaft turbine is exactly what we are looking for to extract power from NT/5. I believe the turbo is made by a company called COMPREX A.G. in Sweden, but I'm not sure. I would like very much to acquire one of these units, please e-mail me if you have any info on this company.

![]() Turbo Compounding Setup (I want one of these units).

Turbo Compounding Setup (I want one of these units).

February 28

Our experiment with hydrogen was a success! Max readings were 49,000 rpm. 22psi, about 35 lbs. thrust, 1,200f EGT, with both propane and hydrogen together. We emptied the hydrogen cylinder in about 10 minutes. Best results to date with NT/5! It would have gone faster but the exhaust nozzle blew off, that caused the compressor to surge which blew the intake screen off. We fixed all that then blew the compressor hose off. Then the intake air bent the tach probe down and the tach stopped working. After all that we were out of hydrogen, so we hooked the both propane tanks back up an it still worked great, I'm not sure why its not flaming out anymore, but it looks like it will run well, as is, with propane. As long as we can get enough propane pressure we don't need the hydrogen. Still lots of little bugs to work out before I will worry about making any thrust. Adequate fuel supply is still a problem.

Today, after a brief consultation with Tim Arfons, I decided to make the change to jet fuel. I purchased a couple of different sized oil burner nozzles from the local heating supply house, we will use a Detroit diesel fuel pump driven by a 0 - 2,800 rpm drill to supply straight kerosene (Jet A). We will do some experiments with the pump and nozzles to see how they work together.

March 06

Bench tested the fuel injection system today after work. We are using a large Detroit diesel fuel pump (3/8 gears), 5 gph 60 deg semi solid oil burner nozzle, 2,800rpm drill. We were able to make well over 200 psi at the nozzle after disabling the pressure relief valve in the pump. Atomization is good at moderate to high flows, dribbles a bit at low flow. I love the smell of burning jet fuel, can't wait to try it in NT/5.

April 25

My brother Steve gave me a hand running NT/5 on Saturday after work. I spent a couple of hours making a stainless support strut for the fiber optic probe unfortunately the probe did not survive the Heli-Arc welding despite my best efforts. We ended up cutting the plastic fibers and zip tying them to the side of the probe, this worked great.

The fuel supply is not such a problem in the warm weather, after leaving both propane cylinders in the sun for a while, the vapor pressure was up to about 115psi. We had an excellent run-up, max speed 54,000 rpm, 18 psi, and enough thrust through the 2 3/4" nozzle to move the entire rig. For the first time, we had to worry about the whole works taking off across the shop floor.

I wanted to see if we could start NT/5 by allowing propane to issue from a torch, directly into the intake screen. We motored the compressor wheel with the start air, turned on the ignition and opened the propane valve... nothing happened, so I partly closed the start air valve to reduce the cranking speed and tried again. There was a huge EXPLOSION and the exhaust nozzle went flying backwards off the tail pipe (I was expecting a "hard start" so we weren't totally surprised), but the explosion ignited the propane which resulted in a FIRE that melted the zip ties and the probe. (We did not expect fire at the torch tip)

I fixed up the probe and cleaned up the mess and were back in business, but then the jet wouldn't run right, it would flame out at about 20,000 rpm. I had not bothered to reinstall the exhaust nozzle because it was too hot to handle. So we stuck the nozzle back on and presto! everything worked great. The only limiting factor at this point is fuel flow. Next I will try propane directly from the cylinder with no regulators, just the shutoff valve. This should make NT/5 rock! (Kids, don't try this at home!)

Propane Delivery Adapter. Includes check-valve. This works slick! (Update: Works even better with a 1/4 turn ball valve between the TEE and the check-valve for use as a throttle).

Propane Delivery Adapter. Includes check-valve. This works slick! (Update: Works even better with a 1/4 turn ball valve between the TEE and the check-valve for use as a throttle).

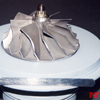

April 25

I made-up a pair of these Propane Delivery Adapters. They consist of a propane tank fitting on one end, a gauge (not really needed) and a Harris regulator outlet bushing/check valve on the other end. We connect the fuel hoses to the outlet checks and blow propane vapor directly into the combustor, unregulated. These work really great, we ran 58,000 rpm @ 15 psi. Unfortunately with all this extra power available we fried the turbine. We saw sparks issue from the jetpipe, I quickly shut both fuel valves, but it was too late, the tips of the turbine blades all have little chunks ripped out from centrifugal force. (You can see it happen on the NT/5 Video) I will have to take the turbo to our supplier for a check-up and a new turbine.

We machined the exhaust nozzle out from 2.75" to 3.0" to reduce the EGT and then did another run-up (still with the damaged turbine). We clocked 61,200 rpm @ 18 psi with so much thrust that a plywood blinder screen that we use in our shop was blown over from 75 ft away! Best yet for NT/5, and that's with a fried turbine! Were happy now!

NT/5 TurboJET.(Checking the air casing clamp).

NT/5 TurboJET.(Checking the air casing clamp).

NT/5 TurboJET.(Hooking up the fuel lines).

NT/5 TurboJET.(Hooking up the fuel lines).

NT/5 TurboJET.(Run-Up).

NT/5 TurboJET.(Run-Up).

May 15

I took the turbo in to our Turbo Supplier today, (Bramall Turbo) they will replace the turbine and bearings. We expect to be back on-line in about two weeks, this time running on Jet-A. We have a new operating rule; From now-on we will not increase the fuel flow when the pyrometer is pegged at 1500°F!

June 02

I got the turbo back, it's as good as new. The fried turbine is worse than I thought. The tips of the blades have all ripped off. You can see exactly where the oil leaves the shaft, its burnt blue beyond that point.

I have painted the compressor wheel nut half black and half white with GM® touch-up paint, this should improve the sensing range of the tachometer.

A visit to SEW Eurodrive in Mississauga proved interesting. The people there were friendly and quite helpful, they have some cool 10:1 planetary speed reducers. They are working on a couple of ideas for a speed reducer that we could use to drive a generator with our proposed free shaft turbine.

October 20

Finally some progress! We now have the A/R 1.70 turbine housing we've been waiting for. With a full range of housings we hope to learn about the effects of turbine A/R on performance. I am hoping the A/R 1.70 housing will yield better results with the big compressor, it should allow a higher flow of gasses to pass through the turbine without producing more turbine speed.

The housings look the same at first but they are very different. Notice how fat the gas passage is on the 1.70, the passage leans away from the center of rotation on the 1.70, straight up (tangential) the 1.50 and in slightly on the 1.14. The 1.14 and 1.70 housings are brand new and have never been on a diesel.

![]()

October 28

WOW! 71,000 rpm, WHAT A BLAST!

With 2 one hundred pounders of propane wide open (no regulators) NT/5 absolutely shrieks! At these speeds everybody runs for cover, its wild. The 1.70 A/R turbine housing works great! We were able to hold steady at 66,000 rpm, 1350egt, 25psig.

We could build one wicked hypercharger for a car with this setup. With unlimited boost on demand and no parasitic loss, an NT/5 based hyper charger on a big block street car would be pretty cool!

Here's what we observed:

- NT/5 is a success! This thing cranks like you wouldn't believe. The energy level is frightening.

- The new tach probe works great. It is much stronger so it can't vibrate and break-off. we can now get reliable rpm readings.

- NT/5 will flame out if the secondary fuel valve is opened before the primary. (The liquid fuel system should solve this) (all radial primary combustor holes are covered by a tin sleeve for this test)

- The 75mm exhaust nozzle is slightly too small. At 66,000rpm the EGT was 1500f.

- With no nozzle spool up was much faster and at 66,000rpm the EGT was 1350f.

- The compressor is surging very badly at high speed. I think we have more compressor capacity than we need for a pure turbojet.

- With the air bleed 3/4 open, the surging is reduced but the EGT rises. (This is good news because we can use the bleed air to cool the after burner. For a free shaft gas-turbine, a smaller compressor may be in order).

- The silicone hose connecting the compressor discharge to the air jacket blew off again. We need to redesign this connection so it can't slip.

Next test run will be with the new 90mm nozzle.

October 29

I bored the existing exhaust nozzle out to 85mm and did another series of test runs today after work. The manager at Speedy muffler was kind enough to expand the air delivery tube for a better fit-up to the compressor hose. A pair of big 3.5" rad hose clamps from Kenworth eliminated any further worry about the hose slipping off under pressure.

At 51,000rpm, EGT was 1300° F compressor 15psi, with little or no surging. Increasing fuel flow would cause the compressor to surge right through to 66,000rpm 1350° F with the pressure gauge fluttering between 17 and 22 psi. Opening the air bleed tends to reduce the surging, decrease the rpm and increase the EGT. With the exhaust nozzle removed the engine would flame out at about 25,500rpm for some reason, it ran right up to 72,000rpm with no nozzle yesterday, what gives?

I had the entire turbine housing red hot for the first time today. A spark shot out of the jet pipe during a high power blast and I thought the worst, but on tear-down we couldn't find any damage, the turbine tips are still like new and the flame tube looks great. (probably a June bug)

The sound this thing makes is incredible! I stood back and removed my ear muffs to see what NT/5 really sounds like. Even at 50,000rpm (I won't leave the controls at higher speeds) the sound is like a shop air gun being blasted right beside your ear, its an intense spraying or rushing sound. You can't hear the whine from the turbine or the oil pump motor at all. And to think we have yet to build an after burner, I can't wait!

November 01

I have added four 20mm holes and four 20 X 25mm ovals in the dilution zone hopping to reduce EGT slightly. And we have rigged up a slick new dilution zone water injection system. (this is where it's going to get real interesting)

Here are some scans of what we have been up to lately.

Inducer Ring. Air start tube and hose fitting on left, tach probe and optic fibers on lower left.

Inducer Ring. Air start tube and hose fitting on left, tach probe and optic fibers on lower left.

Inducer Group. Inducer ring with Mr. Gasket velocity stack installed.

Inducer Group. Inducer ring with Mr. Gasket velocity stack installed.

Water Injection. Looking upstream into the flame tube. Three streams of water visible.

Water Injection. Looking upstream into the flame tube. Three streams of water visible.

Nozzles. Left to Right; 80, 90, and 100mm diameter.

Nozzles. Left to Right; 80, 90, and 100mm diameter.

November 08

The extra holes in the dilution zone were very effective! NT/5 no longer flames out with the exhaust nozzle removed and the EGT at 30,000rpm is down to around 850° F (was 1300). The extra holes worked so well, we will add more.

The size and placement of our flame tube air holes were based on pictures of commercial jet engine combustors. We realize now that since our compressor is producing relatively low air pressure, (30psig as opposed to say 175psig or more in a commercial turbine) we need much larger holes.

The water injection was a partial success. As predicted by a couple of friends on the dtt list, the nozzle placement we chose was not appropriate. We thought the three 0.062" streams of water injected before the turbine would flash to steam instantly. We were wrong, we actually had liquid water bubbling out of the combustor to turbine housing gasket. Opening the water valve at high power increased rpm and lowered EGT somewhat but not the way it should have. We will use a hollow cone spray nozzle aimed at the compressor air intake next time.

I hooked-up a pressure switch and a big red warning light for the oil system to indicate low oil pressure. This takes a load of my mind when running NT/5. We also tilted the instrument panel up for easier viewing. Installing 1/4 turn ball valves on the fuel delivery adapters has made throttling much easier.

Load Cell Calibration. Red tank is for jet fuel (not tried yet), White square is a bathroom weigh scale up against the wall for calibrating the load cell. The white rectangle on the control panel is the tachometer DVM, the digital thrust meter is directly below.

Load Cell Calibration. Red tank is for jet fuel (not tried yet), White square is a bathroom weigh scale up against the wall for calibrating the load cell. The white rectangle on the control panel is the tachometer DVM, the digital thrust meter is directly below.

We have hooked up a meter for the thrust load-cell and will be measuring thrust on every run from now on.

Here is the data from this weekend:

- Run #1 - 100mm nozzle, 35Lb thrust, 25psi

- Run #2 - 80mm nozzle, 52Lb thrust, 25psi, 60,000rpm, 1350f, both bottles cranked.

- Run #3 - 90mm nozzle, 45Lb thrust, 60,000rpm, both bottles cranked.

- Run #4 - 80mm nozzle, 60Lb thrust, 60,000rpm, 1400f, both bottles cranked.

Load Cell Calibration.We used a 20mm steel rod to push against the center of the turbine shaft with a known force to calibrate the thrust load cell.

Load Cell Calibration.We used a 20mm steel rod to push against the center of the turbine shaft with a known force to calibrate the thrust load cell.

With the new turbine housing, the extra dilution holes and the water injection, we are no longer able to get enough fuel from the propane tanks to achieve redline. (75,000rpm) We really need to get the jet fuel system working now.

January 24

NT/5 Run-Up. My brother, Steve Nye has a turn at the controls.(notice the frost line on each propane cylinder)

NT/5 Run-Up. My brother, Steve Nye has a turn at the controls.(notice the frost line on each propane cylinder)

My brother Steve gave me a hand again today after work. We were quite relaxed because we have the NT/5 apparatus fairly well sorted-out now. We can spend more time playing with NT/5 and learning its operating characteristics without worrying about oil pressure and engine speed etc. NT/5 is very easy to start and spool up. It still flames-out periodically on propane but always re-lights easily.

We did some low speed runs and found we could run as slow as 15,000 rpm @ 700°F steady. By adding fuel slowly we could spool right back up to full speed without excessive EGT.

The compressor surges at all speeds above around 36,000 rpm. With the air bleed full open, the surging is reduced, but not eliminated. Even at 72,000 rpm @ 25 psig the compressor is still surging.

Tomorrow we will install a T18A40 compressor wheel and housing.

January 25

NT/5 Rear Side View. During a low speed run.

NT/5 Rear Side View. During a low speed run.

Today I replaced the huge T18A90 compressor with a more normal T18A40. We found NT/5 harder to start and spool-up with the smaller compressor, but the surge was almost totally eliminated and NT/5 seams to sound and run better in general. We still get the occasional flame-out.

Pressure as a function of EGT was much higher. The compressor slaps right over to 30 psig as soon as N1 reaches around 60,000 rpm. I'm sure we could get 35 or 40 psi at 75,000 rpm, but we did not have sufficient fuel pressure to go faster.

We could only get about 50 lbs of thrust @ 60,000rpm - 1,400°F with the 80mm nozzle today. (we've got to get that jet fuel system working soon!)

NT/5 Front Side View. Me and my baby.

NT/5 Front Side View. Me and my baby.

And now for the good stuff.

(Afterburners and free turbines)

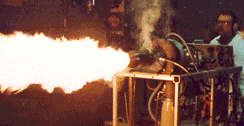

NT/5 Afterburner. Fuel full on and lit, N1 50%

NT/5 Afterburner. Fuel full on and lit, N1 50%

January 31

I finally got a chance to build and run a proper After-Burner. I used a oil furnace nozzle rated for 9.5 gal/min @ 100 psi, we pushed straight kerosene through it at 350psi with a Detroit Diesel fuel pump turned by a 3/8 electric drill. At low turbine speeds the afterburner produces a big lazy yellow flame. As N1 speed increases, the flame gets smaller and more intense.

NT/5 Afterburner. Fuel full on and lit, N1 85%. (The man on the right is driving the After-Burner fuel pump with an electric drill.)

NT/5 Afterburner. Fuel full on and lit, N1 85%. (The man on the right is driving the After-Burner fuel pump with an electric drill.)

NT/5 Afterburner. Detroit diesel fuel pump, throttle valve & gage clamped to the frame on the left. "Hot-streak" oil can on the right for igniting the A/B fuel. Step on the lever for A/B ignition. The "hot-streak" oil is injected into the combustor just ahead of the turbine.

NT/5 Afterburner. Detroit diesel fuel pump, throttle valve & gage clamped to the frame on the left. "Hot-streak" oil can on the right for igniting the A/B fuel. Step on the lever for A/B ignition. The "hot-streak" oil is injected into the combustor just ahead of the turbine.

To light the A/B fuel, we inject motor oil into the combustor (in the failed water injection holes) with a shop oil can. The oil burns and produces a streak of flame that extends through the turbine and into the afterburner.

NT/5 Afterburner Nozzle removed, looking up the tail pipe at the flame holder.

The vapor gutter or flame holder is the shiny ring surrounding the A/B nozzle. It produces an eddy that prevents the flame from being blown out of the after-burner.

NT/5 with T18A40 free turbine mounted.

We have been doing some experiments with a free turbine. The second turbo is mounted on the first with a short transition duct. This setup is not matched properly and produces very high exhaust gas temperatures, to correct this, we need to use a larger free turbine or a smaller gas producer turbo.

NT/5 Free Turbine Adapter piece for coupling turbos together. The fitting on the top is for inter turbine pressure and the one on the side is for inter turbine temperature (ITT). This piece is made of 304L stainless steel. It connects to the output of the gas producer turbine with the factory "V" band clamp.

NT/5 Free Turbine Adapter piece for coupling turbos together. The fitting on the top is for inter turbine pressure and the one on the side is for inter turbine temperature (ITT). This piece is made of 304L stainless steel. It connects to the output of the gas producer turbine with the factory "V" band clamp.

NT/5 Free Turbine Rear view. This setup acts like a dyno, the second turbo provides a variable load for the gas producer section. The screen over the air intake is mandatory. Note the oil supply and drain lines on both turbos.

NT/5 Free Turbine Rear view. This setup acts like a dyno, the second turbo provides a variable load for the gas producer section. The screen over the air intake is mandatory. Note the oil supply and drain lines on both turbos.

Hispano Suiza Turbo Here is a big beautiful turbo from a marine diesel. I would love to build a jet with one of these, perhaps Hispano Suiza would donate one to the cause?

Hispano Suiza Turbo Here is a big beautiful turbo from a marine diesel. I would love to build a jet with one of these, perhaps Hispano Suiza would donate one to the cause?

We will continue to update and improve this page as the NT/5 project progresses and as time permits.

Here is a lo-res sample of what's on the NT/5 video:

See the Turbo Turbine Article that appeared in the NewScientist Magazine

See the Turbo Turbine Article that appeared in the NewScientist Magazine

![]() Click here to download Acrobat Reader.

Click here to download Acrobat Reader.